HOW DRUMS ARE MADE

Raw Materials

Until the late 1950’s, the top of a drum was almost always made of animal skin. Now, modern heads are almost always made of plastic. Usually some form of polyester is used. The shell of the drum is usually made of wood. The wood in a drum set includes maple and birch. Some drums have a metal shell. The metal in a drum set include steel, aluminum, brass, and bronze.

The Manufacturing Process

Making The Hardware Component

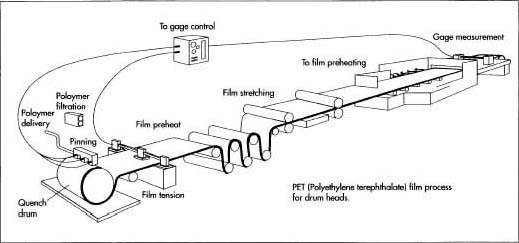

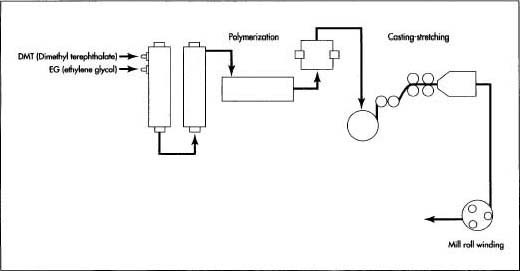

Drumhead material is made by cooling hot liquid plastic on a big metal roller to form a solid surface. Then, it is stretched between smaller metal rollers to have a thin film. The wood hardware components are carved from blocks of wood using many different cutting tools.

Making The Head

Chemicals are subjected to heat to produce hot, liquid plastic. The liquid is cooled on a large metal roller to form a solid surface. Then, stretched between smaller metal rollers to have a thin film. Then, proper sizes to make drumheads are cut from the film using cutting tools. The edge of the plastic circle is softened by a heading element and allowing it to cool to form a collar around the circle. Next, a steel ring is placed within the collar and an aluminum ring is placed outside of the collar.

Making The Shell

Metal shells are made using a variety of methods including casting and machining. Plastic shells may use injection molding. Most shells are made out of wood. Wooden shells are made from huge, thin panels of wood know as veneer. Veneer is cut from lumber with big saws and shipped from the lumber company to the drum manufacturer. Veneer is cut to the proper size to make the shell by a computer-controlled saw. The cut pieced are sorted by size and stored under controlled temperature. The pieces of veneer are rolled together to form a cylinder consisting of 7-9 pieces of wood. The rolled veneer is inserted into a metal mold of the proper size to made the desired shell. Then, the shell is removed from the mold. It is then cut with a fast rotating blade to produce a 45-degree angle on its edge. Finally, the shell is sanded with high power sanders to produce a smooth surface. It is then stained or covered with a sheep of pretty, shiny decorative plastic in many different colors and patterns.

Assembling The Drum

Drills are used to drill holes in the shell to allow the hardware components to be attached. Lugs, which hold the head in place, are screwed into the shell. Then, long, thin metal rods, known as tension rods, pass through the aluminium ring surrounding the head and into the lugs. Using a drum key, which tightens or loosens the tension rods, can control the degree of tension on the head. Finally, the drum is put in a plastic bag.